- #BARCODE SYSTEMS FOR INVENTORY CONTROL HOW TO#

- #BARCODE SYSTEMS FOR INVENTORY CONTROL PORTABLE#

- #BARCODE SYSTEMS FOR INVENTORY CONTROL SOFTWARE#

- #BARCODE SYSTEMS FOR INVENTORY CONTROL CODE#

Maintenance, repair, and operating (MRO) suppliesĬorrectly labeling inventory by function aids your accounting processes.Step 2: Define barcode functionsĭefine your inventory barcode functions because "inventory" applies to a wide variety of assets, such as items you've made, items you bought to resell, and items you bought to use.

Two-dimensional barcodes such as QR codes store more data than one-dimensional UPC barcodes.

#BARCODE SYSTEMS FOR INVENTORY CONTROL CODE#

Your barcode choice also depends on the size you need - Data Matrix barcodes can go on small items while Code 39 barcodes must be larger to scan correctly - and how much information it stores.

#BARCODE SYSTEMS FOR INVENTORY CONTROL HOW TO#

How to make a barcode inventory system for your small business

#BARCODE SYSTEMS FOR INVENTORY CONTROL PORTABLE#

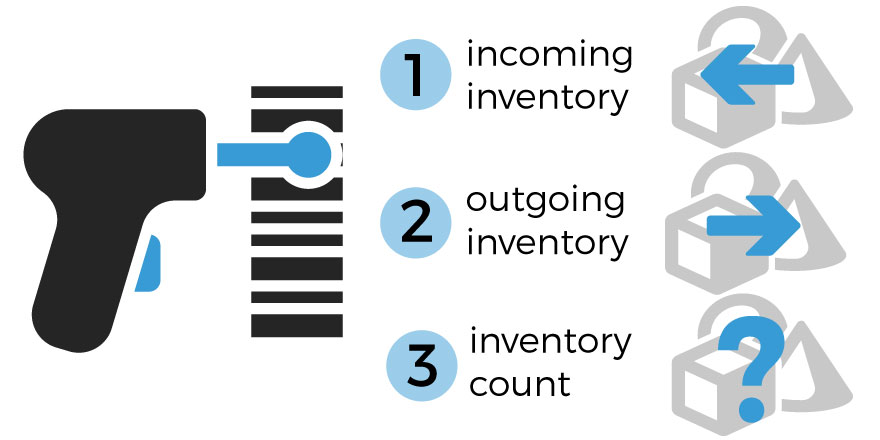

Do you need portable inventory scanners or fixed, flatbed scanners? Will you scan one barcode type or many? What are the environmental conditions where you'll use your scanners? You must also decide what kind of barcode hardware to use. If you have a large amount of products, multiple warehouses, or are a logistics provider, you may want to invest in inventory-specific barcode software. If you have a retail operation, you can probably use your POS system to create barcodes. But it can perform other functions, depending on your needs: theft prevention, order fulfillment speed, and first-in, first-out (FIFO) accounting. Sure, barcode inventory management keeps you updated on what you do and don't have in stock.

#BARCODE SYSTEMS FOR INVENTORY CONTROL SOFTWARE#

You'll also have more data for inventory control processes such as setting safety stock levels, calculating reorder points, and determining economic order quantity (EOQ).īefore you print barcodes and put them on products, however, identify what you want to achieve from a barcode inventory system and assess your software and hardware needs.

You'll enjoy multiple benefits from using barcodes to track inventory, starting with perpetual inventory counts instead of a periodic inventory system. What to consider when creating a barcode inventory system Source: The advantage of using your own SKUs instead of UPCs is they store more information than the product name and manufacturer, including store location, department, item category, size, and color. SKU barcodes are used in retail environments. Over 30 major barcodes with different applications exist today, everything from Bookland EAN-13 barcodes that embed product, publisher, and pricing data on the back of a book to single-use barcodes with shipping information. A two-dimensional barcode is either square, such as a QR code, or rectangular and consists of many dots, which can store much more information.

Introduced in 1951, adoption was not widespread until supermarkets began automating the grocery checkout process in the mid-1970s with universal product codes (UPCs).Ī UPC barcode identifies two pieces of information: the product and its manufacturer.Ī UPC is a one-dimensional barcode: Data is encoded using different widths of parallel lines and spacing between them. We'll go over barcode basics and the steps to set up your own system, so you can decide if your small business would benefit from implementing one to aid in your inventory management.Ī barcode is the visual representation of data using lines and spacing, which is readable by digital scanners. We could have avoided that hassle - and likely sold more merch, too - with a barcode inventory system. The owners' inventory management "system" consisted of us running to a storeroom to dig through confusingly labeled plastic containers to see what was in stock. I always cringed, though, when someone asked which brewery t-shirt styles and sizes were in stock versus what was on display. Using the barcodes you can quickly respond about the any changes of a particular product.When I worked part-time in a craft beer brewery taproom, the pouring beer part was never a problem. Since the barcode works in process can move quickly so that you can save your valuable time. Bar codes system provide faster and accurate recording of data.

0 kommentar(er)

0 kommentar(er)